Tredor Trading

Outdoor Furniture

The 2026 Best Chemical Raw Materials Manufacturer Insights?

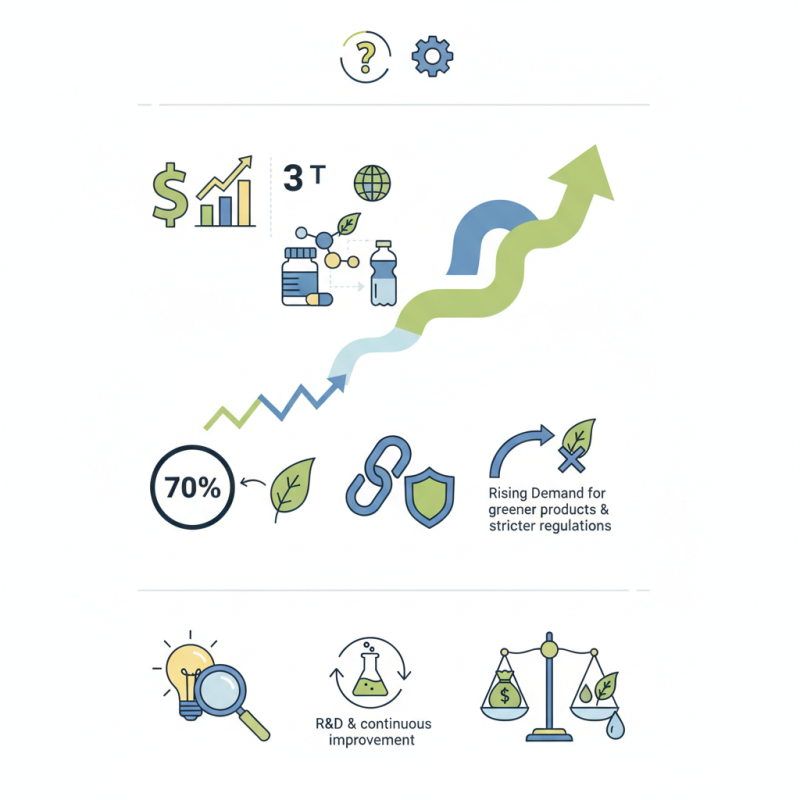

The landscape of the chemical industry is evolving rapidly. According to the Global Chemical Raw Materials Market Report, the market is expected to reach $3 trillion by 2026, highlighting the significance of chemical raw materials manufacturers. These companies are pivotal in supply chains across various sectors, including pharmaceuticals and plastics.

Despite this growth, challenges persist. Many manufacturers face issues in supply chain resilience and sustainability. In fact, 70% of these companies struggle with sourcing eco-friendly materials. The demand for greener products is rising, driven by consumer awareness and stricter regulations.

The importance of innovation cannot be understated. Manufacturers need to invest in R&D. It is essential for staying competitive. Only through continual improvement can they enhance product quality and reduce environmental impact. The best chemical raw materials manufacturer will be one that balances profitability with sustainability, addressing both market demands and ethical responsibilities.

Overview of the Chemical Raw Materials Industry in 2026

As we look ahead to 2026, the chemical raw materials industry faces several changing dynamics. The demand for sustainable materials is rising. Limited resources push manufacturers toward innovation. Companies are investing in eco-friendly production methods. This shift is crucial for long-term success.

Consider these tips for navigating the industry landscape in 2026. Embrace sustainability. It’s not just a trend; it’s a necessity. Focus on resource efficiency. Reducing waste can lead to cost savings. Keep an eye on regulatory changes. Staying informed can prevent costly compliance issues.

The market will likely see increased competition. New players may disrupt traditional models. Innovation can be a double-edged sword. Companies must balance risk and opportunity carefully. Adaptability will be key to thriving in this environment.

Key Players in the 2026 Chemical Raw Materials Manufacturing Sector

The chemical raw materials manufacturing sector is evolving rapidly. It is projected that this market will reach a value of over $1 trillion by 2026. Key players dominate in both innovation and production efficiency. They are focusing on sustainable practices while increasing output. The shift to bio-based chemicals and materials is significant. According to industry reports, bio-based raw materials could account for 25% of the market share by 2026.

However, challenges persist. Many manufacturers still rely on traditional fossil fuel-based processes. This can hinder progress toward sustainability goals. The transition requires investment in research and development. Companies must also adapt their supply chains to reduce environmental impact. Inadequate infrastructure can slow down these necessary changes.

Cost pressures are another issue. Prices of raw materials are volatile. Companies often struggle to pass these costs onto customers. This creates tension between profitability and sustainability initiatives. Industry reports highlight that many manufacturers are reconsidering their strategies. They need to balance immediate financial pressures with long-term environmental responsibilities.

The 2026 Best Chemical Raw Materials Manufacturer Insights

| Manufacturer Type | Production Capacity (tons/year) | Revenue (Million USD) | Number of Employees | Headquarters Region |

|---|---|---|---|---|

| Synthetic Chemical Manufacturer | 350,000 | 500 | 1500 | North America |

| Specialty Chemical Manufacturer | 250,000 | 400 | 1000 | Europe |

| Basic Chemical Manufacturer | 500,000 | 800 | 2500 | Asia |

| Pharmaceutical Raw Material Manufacturer | 150,000 | 300 | 800 | North America |

| Industrial Chemical Manufacturer | 200,000 | 350 | 1200 | Europe |

Trends Influencing Chemical Raw Materials Production and Supply Chain

The chemical raw materials industry is undergoing significant transformations. Sustainability trends drive manufacturers to adopt greener processes. Raw material sourcing is now closely tied to eco-friendliness. Companies are under pressure to reduce their carbon footprints. As consumer awareness grows, demand for sustainable products increases.

Supply chain challenges are also prominent. Geopolitical situations impact material availability. Trade restrictions can disrupt the flow of essential chemicals. Companies must remain agile and adaptable to these changes. Collaboration with suppliers can enhance resilience.

Tip: Always assess the sustainability of your suppliers. Look for certifications that demonstrate eco-friendly practices.

Innovation is key to staying competitive. Investment in research can lead to breakthroughs. However, not all innovations succeed. Some may require several iterations to perfect. Yet, the industry must embrace failure as part of the growth journey.

Tip: Regularly review your processes. Identify areas for improvement and be open to feedback. This can foster a culture of continuous innovation.

Technological Innovations in Chemical Manufacturing for 2026

As we look ahead to 2026, the chemical manufacturing sector is ripe for transformative innovations. The shift towards sustainable methods is evident. A report by McKinsey suggests that up to 70% of manufacturers are investing in green chemistry technologies. This includes bio-based materials and processes that reduce environmental impact. For instance, bioplastics derived from renewable resources are gaining traction, aiming to replace conventional plastics.

Moreover, automation and AI are revolutionizing production lines. According to an industry study, over 50% of companies are adopting AI-driven solutions. These technologies enhance efficiency and reduce waste. However, not all manufacturers can keep up. Smaller firms often struggle with the high initial costs of these technologies. There is a growing concern about a widening gap between industry leaders and smaller players.

In addition, data analytics is playing a crucial role. Utilizing real-time data can improve decision-making processes. Yet, the complexity of data management is a challenge for many. Ensuring data accuracy and security is paramount. As the industry evolves, the balance between innovation and accessibility will be critical for overall growth.

Sustainability Practices Among Leading Chemical Raw Materials Manufacturers

Sustainability is a critical focus among chemical raw materials manufacturers. Many industry leaders are prioritizing eco-friendly practices. According to a recent sustainability report, over 70% of manufacturers aim to reduce their carbon footprints. This commitment to sustainability is reshaping the market.

Energy consumption remains a challenge. Nearly 40% of companies still rely heavily on fossil fuels. Transitioning to renewable energy sources proves difficult. Many firms combat this by investing in energy efficiency technologies. For instance, some report a 15% reduction in energy use after upgrading equipment.

Water management practices also require attention. A study indicated that 30% of manufacturers lack comprehensive water conservation plans. This raises concerns in water-scarce regions. Effective strategies are crucial to avoid potential shortages. Some firms implemented closed-loop systems, reducing water waste significantly. Yet, many still struggle with real-time monitoring systems. The journey toward sustainability is ongoing.