Tredor Trading

Outdoor Furniture

Best Rubber Air Hose Types and Their Uses Explained?

In the world of pneumatic systems, a rubber air hose plays a crucial role. According to John Smith, a leading expert in the field, "Choosing the right rubber air hose can enhance efficiency and safety." This statement emphasizes the significance of understanding various hose types and their applications.

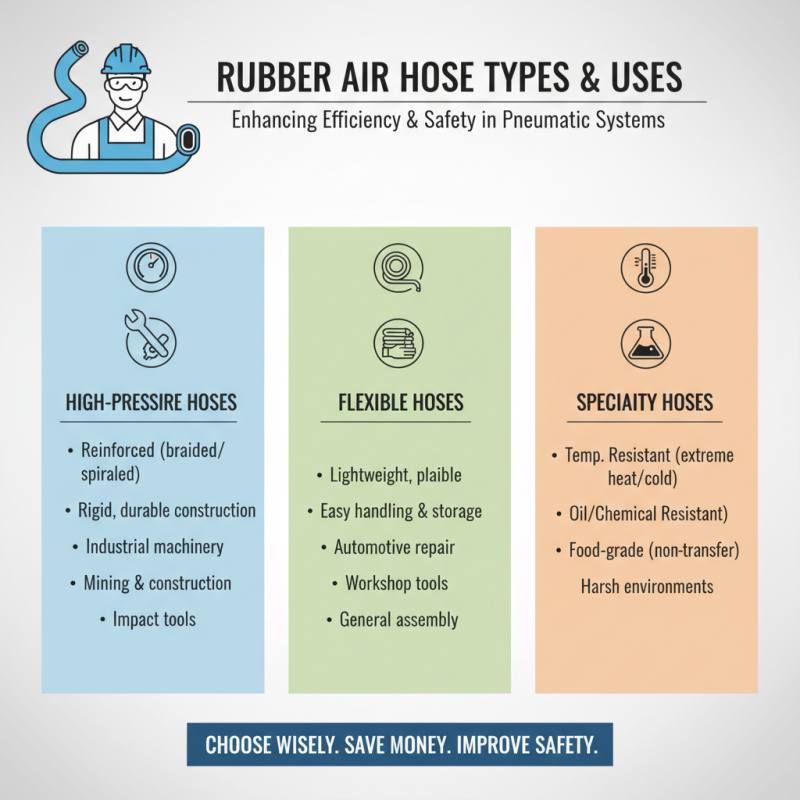

rubber air hoses come in many forms. Each type serves unique purposes. For instance, some are designed for high-pressure applications, while others are more flexible for varied tasks. This diversity can be overwhelming. Many may struggle to select the right one for their needs. Picking an incorrect type can lead to inefficiency or even accidents.

Not all rubber air hoses are created equal. Factors like temperature tolerance and reinforcement vary significantly among them. Users must consider their specific requirements. It's worth reflecting on the long-term benefits of investing in the right hose. A poor choice can lead to frequent replacements, ultimately costing more. Understanding these elements is vital for making informed decisions in this essential industry.

Overview of Rubber Air Hose Types

Rubber air hoses come in various types, each designed for specific applications. They are lightweight and flexible, making them easy to handle. Among the most common types is the standard rubber air hose. This type is duralbe and suitable for general use in workshops and garages. It can withstand high pressures, which makes it ideal for a range of pneumatic tools.

Another type is the reinforced rubber air hose. This hose features additional layers for added strength. It is perfect for heavy-duty applications where abrasion resistance is crucial. The anti-kink design helps prevent disruptions in airflow, but it may be less flexible.

Then there's the multi-purpose rubber air hose. This versatile option caters to various tasks, from inflating tires to powering air tools. However, one should consider the compatibility of hose diameters with devices being used.

When selecting an air hose, it’s essential to think about the application and environment. Noticing the hose’s weight can be significant; some may find lighter hoses easier to manage. Remember, using the wrong type can lead to inefficiencies. Users often overlook this detail, which can result in frustration and wasted time. Choosing the right rubber air hose requires thought and understanding of those specific needs.

Common Uses for Rubber Air Hoses

Rubber air hoses are popular for various applications. Their flexibility and durability make them ideal for many projects. In workshops, they are often used to connect air compressors to tools. You can find them in garages, factories, and construction sites. Their ability to handle different pressures is a significant advantage.

In farming, these hoses help power pneumatic tools. They can also be used for inflating tires or running machinery. Industries rely on them for everyday tasks. However, improper handling can lead to damage. Make sure to check for cracks and wear regularly.

Tips: Always store hoses in cool, dry places. Avoid sharp bends, as they can weaken the material. Also, keep them away from hot surfaces. Proper care can extend their lifespan significantly. Remember, a little maintenance goes a long way!

Key Features to Consider When Choosing a Rubber Air Hose

When choosing a rubber air hose, consider key features that enhance its performance. Length matters. A longer hose provides more reach but can also cause pressure loss. Think about your workspace. If your tasks require mobility, a shorter hose may be beneficial.

Another important aspect is the diameter. A wider diameter allows for increased airflow, which is vital for heavy-duty tools. On the other hand, a narrower diameter may suffice for lighter tasks. Flexibility is crucial, too. A flexible hose can bend around corners and tight spots, but it might also kink or twist easily.

Lastly, check the temperature rating. Some hoses can handle extreme temperatures, while others may degrade in heat. Durability is essential for both daily use and storage. A hose that doesn't hold up under pressure or wear may not be a wise investment, even if it looks good initially. Weigh these factors carefully to find the right air hose for your needs.

Maintenance Tips for Extending the Life of Rubber Air Hoses

Rubber air hoses are essential for various tasks. However, they can degrade quickly without proper care. One of the main issues is UV exposure. Sunlight can cause rubber to crack and become brittle. Store hoses in a shaded area or indoors when not in use. This simple step can greatly extend their lifespan.

Another critical factor is how you handle the hoses. Avoid dragging them across rough surfaces. This can create wear and tear, leading to leaks. Instead, lift them gently when moving. Regularly check for any signs of damage or wear. Small cracks or kinks can turn into bigger problems. Inspect your hoses, and replace them if necessary.

Proper cleaning is also vital. Use mild soap and water to clean the hoses. Avoid harsh chemicals that can damage the rubber. After cleaning, make sure to dry the hoses before storing them. It prevents mildew and prolongs their life. Think about these tips regularly. Your hoses deserve the best care.

Comparative Analysis of Rubber Air Hoses versus Other Hose Materials

When discussing the comparative analysis of rubber air hoses versus other hose materials, understanding the strengths and weaknesses is crucial. Rubber air hoses excel in flexibility and durability. In contrast, plastic hoses are lighter but may lack the necessary resilience in harsh environments.

Data from industry reports indicate that rubber hoses can withstand extreme temperatures, ranging from -40°F to 200°F. This makes them ideal for heavy-duty applications. Meanwhile, PVC hoses tend to perform poorly under high pressure, leading to potential failures in critical situations.

Tips: Choose rubber hoses if your work involves heavy machinery or outdoor settings. They resist wear and can handle tough conditions effectively. However, be cautious; the weight of rubber hoses can be a downside for mobility. Evaluate your application before making a purchase. Would you sacrifice weight for durability?