Tredor Trading

Outdoor Furniture

Top Ball Screw for Sale Options in 2026 to Consider?

As we approach 2026, the demand for high-quality ball screw for sale options continues to rise. Ball screws play a crucial role in various applications, delivering precision and efficiency in motion control systems. It can be overwhelming to choose from numerous options available on the market. Each choice has its pros and cons, making it essential to examine them closely.

In this dynamic landscape, manufacturers are increasingly innovative. They offer designs that cater to specific industrial needs. However, some products may not meet expectations despite impressive specifications. Buyers may find themselves navigating a web of marketing jargon without clear guidance. This situation calls for a critical approach in evaluating ball screws for sale.

When investing in ball screws, you want quality and reliability. The goal is to enhance performance while avoiding costly mistakes. Understanding what makes a ball screw suitable for your needs can make all the difference. Knowing the limitations and potential issues is key to making informed decisions. As new options enter the market, staying informed will help you select the best ball screw solutions for your projects.

Overview of Ball Screws and Their Applications in Industry

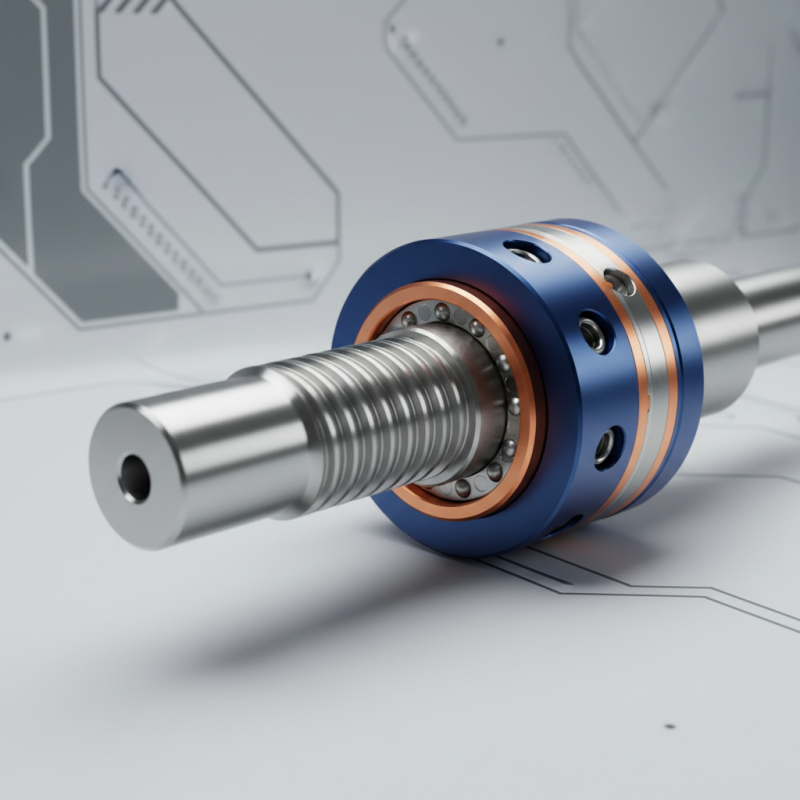

Ball screws play a critical role in various industrial applications. These mechanical devices convert rotary motion into linear motion. They are essential in machining tools, robotics, and automation systems. Their design provides excellent precision, efficiency, and reliability. This makes them highly valued in industries that require accurate movement.

In manufacturing, ball screws are often used in CNC machines. The precision they provide is vital for high-quality production. However, they can be sensitive to load variations. Underestimating the load can lead to performance issues. Additionally, regular maintenance is crucial. Neglected ball screws can wear out quickly, impacting productivity.

Another application is in the aerospace sector. Here, they enable precise control of actuators. However, the harsh environment poses challenges. High levels of vibration and temperature fluctuations can affect performance. Organizations must consider these factors when selecting ball screws. Each application requires careful consideration and reflection on the specific needs of the project.

Key Features to Look for When Selecting Ball Screws

When selecting ball screws, certain key features should be prioritized. The screw's pitch is essential. A fine pitch can provide high precision but may reduce speed. Conversely, a coarse pitch offers greater speed but at the potential cost of accuracy. Understanding the right balance for your application is crucial.

Another aspect to consider is the material quality. Ball screws are often made from steel or stainless steel. The choice of material affects durability and resistance to wear. High-quality materials tend to have a longer lifespan. Be wary of low-quality options; they may seem appealing but often lead to frequent replacements.

Understanding the load rating is also vital. It determines how much weight a ball screw can handle without failing. Overloading a screw can lead to performance issues and safety hazards. It’s important to calculate the expected load accurately. A mismatch here can cause serious problems, leading to costly downtime.

Top Manufacturers of Ball Screws in 2026

In 2026, the landscape for ball screw manufacturers will be competitive. Many companies will focus on innovation and quality. They aim to meet the demands of various industries, from automation to aerospace. Manufacturers will invest in research and development to enhance precision and durability. They will also look at ways to reduce production costs.

While some manufacturers excel, others may struggle. Issues like supply chain disruptions can hamper growth. Companies need to remain agile in a changing marketplace. Moreover, customer feedback will play a crucial role in shaping future designs. Listening to users can lead to better products.

Choosing a reliable ball screw manufacturer will be vital. Inspect their certifications and quality assurance processes. Examine their history in the field. A company’s reputation can reveal a lot about its future potential. Balancing these factors can lead to informed decisions, but it’s not always easy. The process may require patience and careful evaluation.

Top Ball Screw Sales in 2026

Comparison of Pricing and Value for Ball Screws on the Market

In 2026, the ball screw market is expected to grow significantly. Recent industry reports indicate that the global ball screw market could reach a valuation of $4.5 billion by 2026, showcasing a compound annual growth rate (CAGR) of around 5.2%. This increase reflects higher demand in automation and manufacturing sectors.

Pricing for ball screws varies widely based on specifications. Standard models generally range from $100 to $500. Custom designs can exceed $1,000. It’s crucial to balance price with performance, especially for precision applications. Investing in high-quality components can yield longer service life and better efficiency.

Tip: Always evaluate your application needs before purchasing. Choose a ball screw that matches your load, speed, and accuracy requirements.

Some manufacturers have focused on reducing costs with low-quality materials. This trend raises concern about durability and performance in critical applications. Weigh the long-term benefits of quality versus the initial savings when selecting your ball screw.

Tip: Look out for comprehensive warranties. A good warranty often signals reliability and quality. Ask about return policies if the product doesn’t meet your needs.

In conclusion, careful price comparisons coupled with an understanding of material quality will help in making informed choices. Stay updated on market trends to ensure you select the best options for your projects.

Emerging Technologies Influencing the Future of Ball Screws

The landscape of ball screw technology is evolving rapidly. Innovations are emerging, pushing the boundaries of performance, efficiency, and sustainability. Advanced materials are being adopted, enhancing load capacity and durability. Manufacturers are exploring lightweight composites that reduce overall system weight. These changes could redefine how industries approach machinery design and fabrication.

Integration with smart technologies is another trend shaping the future. IoT-enabled ball screws may provide real-time feedback and performance analytics. This shift allows for predictive maintenance, potentially reducing downtime. However, implementing such technologies can introduce challenges. Not all manufacturers are equipped to adopt these advancements quickly. The skills gap in the workforce may hinder progress, requiring significant training efforts.

Additionally, adapting to changing regulations on materials and energy efficiency can be daunting. Companies must reflect on their processes to comply with new standards. Those who don't adapt might face increased costs or operational delays. The question remains: how can businesses balance innovation with practicality? The journey ahead is both exciting and uncertain.

Top Ball Screw for Sale Options in 2026

| Type | Load Capacity (N) | Lead (mm) | Diameter (mm) | Material | Price Range (USD) |

|---|---|---|---|---|---|

| Standard Ball Screw | 5000 | 20 | 25 | Steel | $150 - $300 |

| Ball Screw with Nut | 7000 | 25 | 30 | Alloy Steel | $200 - $400 |

| High Precision Ball Screw | 10000 | 10 | 20 | Stainless Steel | $300 - $600 |

| Miniature Ball Screw | 1000 | 5 | 10 | Carbon Steel | $100 - $200 |

| Ball Screw with Linear Guide | 8000 | 15 | 35 | Alloy Steel | $250 - $500 |